Electricity is one of the most important utilities in the workplaces, production sites, buildings where we live, etc. Proper selection of cables is the basis for the failure-free operation of the electrical installation. Another, equally important, is the correct arrangement of the wires. Experience shows that it is not worth taking shortcuts and laying wires without following the basic rules. Errors resulting from apparent savings on the number of wires and carelessness will have very negative effects. A badly made installation will have to be corrected, and the costs of this work may well exceed the profits from the original work. What are the most common mistakes?

Insufficient number of sockets

Too few sockets in the rooms is a typical ailment even in completely new buildings. The result is obvious discomfort and usually a tangle of various extension cords and adapters. In general, it is difficult to find someone who complains about the excess of sockets, but many feel they are a shortage. The number of sockets should be adapted to the number of different devices that will be located within a short distance.

Incorrect cable routing

Electrical cables are arranged along vertical and horizontal lines. The main thing is that their arrangement should be easy to recreate. Thanks to this, we will not damage them, e.g. when drilling a hole in the wall. It is worth reserving zones near the floor, under the ceiling, and at a certain distance from window and door openings as the installation location. This will bring peace of mind in the future – the wires won’t be damaged, e.g. when replacing windows. Errors made while routing cables are particularly troublesome for the users. Failure to comply with the basic rules causes problems in the modernization and expansion of the installation and the popular problem with mounting any elements on the walls that require drilling holes.

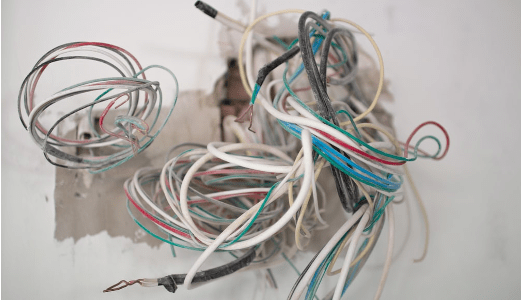

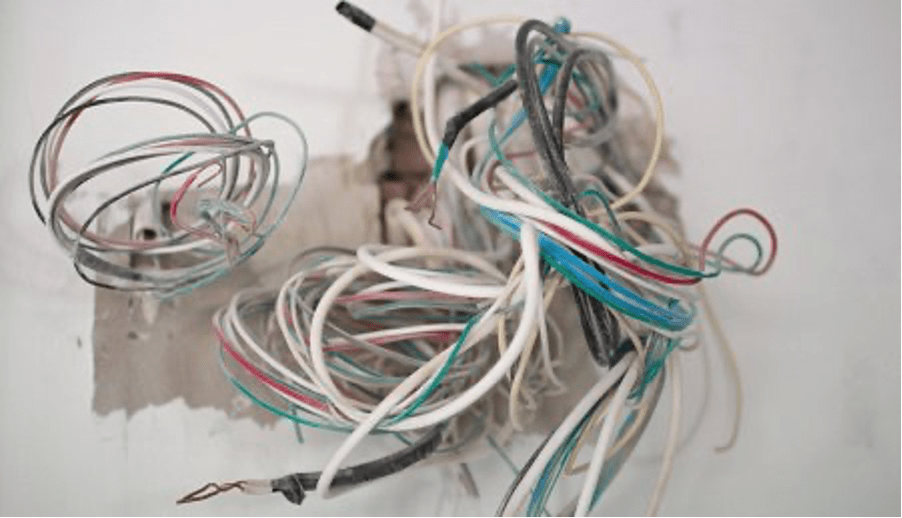

Lack of aesthetics and order

Installation of cable trays can be done correctly, but unsightly. These can be crooked connectors and sockets, or cables run over the top of the walls, in masking strips. And although it does not affect the efficiency of the installation, it does not look attractive. Paying attention to details is very important. Everything should be done right. It is worth choosing contractors who pay attention to such things. By choosing to cooperate with eryk.com you will never experience such mistakes and mess. Electrical teams from Eryk are known for pedantically laid cables and other works connected with such task.

Not enough electrical circuits

Dividing the electrical system into too few circuits is a very common problem. Often this is the result of savings, but it can have very negative effects in the future. Too few circuits can be dangerous. All it takes is a slight failure in one of the power sources to cause all others in the circuit to fail.

Cable work and cable pulling contractors

There are many companies specialising in cable work and cable pulling projects. While looking for a technical service provider, make sure you did proper research. Check if the company has authorisations and a good track record. For sure there will be some projects listed on the website. Another thing is Health and Safety, which is a MUST in the industrial business.

Don’t forget about the Quality. Each cable works- and cable pulling contractor should have a proper quality management system. Check if the company works under internationally respected standards. This is a big value and a guarantee of properly performed installations.

Examples of good contactors within this field? Check eryk.com