Checkweighers are used to weigh items in motion, helping organizations meet their production needs and legal requirements. They also help companies provide a high level of quality and reliability to customers.

Checkweighers can be integrated with other manufacturing equipment to improve production. Some suppliers even offer complete packaging lines that incorporate these machines with bagmakers, vertical form fill and seal machines, traysealers, and inspection systems.

Piece of Equipment

A multihead weigher is a piece of equipment that splits bulk product into smaller volumes, based on pre-programmed limits. It will have many features, including weigh buckets, feed buckets, infeed funnel, feeder pans and a top cone.

When selecting a multihead weigher, you will need to consider accuracy and speed. Accuracy is important because it helps you control the amount of give-away in your product.

Avoid Product Errors

It also helps you avoid product errors. If you have a product with high levels of fat, for example, you can use a multihead weigher that is accurate to less than a tenth of a gram.

It can be used for a wide variety of products, including raw materials, granules and powders. It can even be used to mix a single product into a blend, ensuring that the correct blend proportion goes into every package.

Heart of Checkweighers

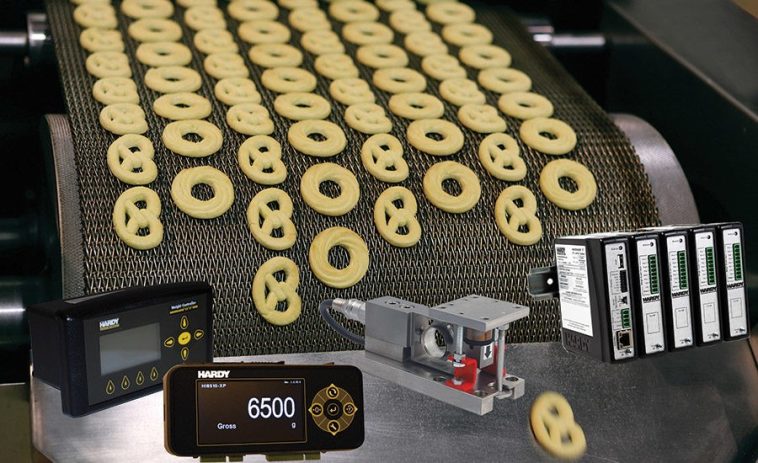

Load cells are the heart of checkweighers, providing force measurement capability and delivering weight data to a checkweigher’s control panel. They’re critical to many industrial weighing applications, including pallet scales, belt weighers, conveyor scales and floor scales.

Mechanical Strain

In general, load cells use strain gauges to measure mechanical strain on the load cell sensor’s metal plate. When a load is applied, that strain causes the lever arm on the load cell’s side to deviate from its nominal resting position.

Digital Signal Processor

The deviations are detected by a photoelectrical beam and sent through a measurement resistor to an advanced digital signal processor, which transforms them into a digital weight value. These weight values are then transmitted to the control panel on a checkweigher or another third-party OEM device or machine.

The belt conveyor is a part of the overall checkweigher system and is used to transport items between scale sections. It is a very common type of conveyor used in the logistics, postal sorting and warehouse industries.

Snubbing Rollers & Return Idlers

The conveyor has a number of different components that make up the system including: a centre drive, tail pulley, snubbing rollers and return idlers. It also has a gear reducer and drive motor.

In many cases, the conveyor will have a tripping mechanism along the sides which can be used to stop the conveyor in case of a problem. This allows the operator to quickly shut down the system.

Accuracy of the System

The belt conveyor will also need to be adapted for the type of products being weighed and the environment they are being handled in. For example, products that are very fragile or corrosive will require special features to ensure the accuracy of the system.

Manageable & Effective

A checkweigher supplier should offer a range of controls, including indicators, reject devices and alarms. All of these can help make the production line more manageable and effective.

Quality & Reliability of Packaged Products

Product inspection is crucial to ensure the quality and reliability of your packaged products. This can include metal detection and product labeling.

Depending on the type of product being processed, a checkweigher can divert inferior product off the production line and reduce rework by removing any defective or damaged goods.

These systems also increase equipment effectiveness (OEE), monitor weight to reduce product give-away, maximize efficiency and help maintain consistent product throughput.

Conclusion:

Kenwei Solutions offers a Dynamic Checkweigher line with control systems that fit customer processes, eliminating overfills and offering easy operation and low cost of ownership.